DELTA PT®

Teknik Özellikler

-

Overview

- Standard length: approx. 2 to 10 x nominal diameter (other on request)

- Standard diameter: from 1 to 10 mm (other on request)

- High load capacity direct fastening into plastic material

- High fatigue strength

- Easy design engineering with the EJOT® DELTA CALC prognosis programme

- Safety due to high tensile and torsion strength as well as vibration resistance

- A wide range of possible tightening torques

- You can access brochures and CAD data at the password protected "CAD & more" area

- Lightweight design: use of shorter fasteners and/or smaller diameters possible under certain conditions

Hotline

Applications Engineer

All-rounder" in plastic

The EJOT DELTA PT® screw is a special fastening element for reliable and easy direct assembly into thermoplastic. It is the consequent optimisation of the EJOT PT® and the result of long-time development and operating experience in the field of direct assembly of even highly loaded thermoplastic materials. The possible range of uses includes all industrial applications. Especially in the automotive industry, where the used components have to withstand very high loads, the DELTA PT® screw has been established as a reliable and durable fastener.

Individual design engineering assistance

The EJOT DELTA CALC®, a prognosis programme based on the mechanical parameters of many thousand applications and test assemblies, is a valuable support for the pre-dimensioning of direct assembly into thermoplastic. Stored in this tool are the fastening parameters of the DELTA PT® screw according to material and pilot hole dimension. This saves time already during the design stage of a component.

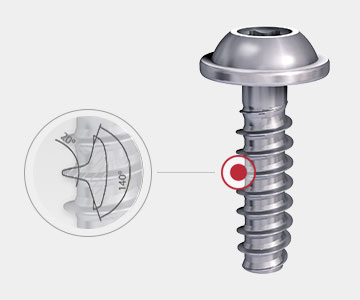

Innovative thread geometry

The special thread geometry of the EJOT DELTA PT® is the result of consequent analysis of the material displacement during thread-forming. The flank angle of this screw reduces the radial stress compared to common thread flanks with 60° flank angles. Since the 20° or 30° angle respectively, generates only slight radial stress a thin-walled design can be realised. The thread flank also guarantees optimum material flow of the formed plastic even with reinforced thermoplastic. The ideal pitch of the DELTA PT® screw was determined by the balanced ratio of highest possible clamp load and low surface pressure in the plastic. This pitch realises very high thread engagement even at small installation depths.

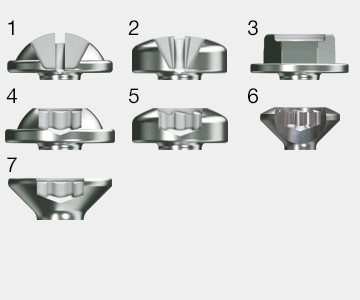

DELTA PT® WN54 Head Styles and Drives

WN5411 round washer head with cross-recess Z (or H)

WN5412 pan head with cross recess Z (or H)

WN5447 hexagon washer head

WN5451 round washer head with TORX PLUS®/AUTOSERT

WN5452 pan head with TORX PLUS®/AUTOSERT

WN5453 oval countersunk head with TORX PLUS®/AUTOSERT

WN5454 flat countersunk head with TORX PLUS®/AUTOSERT

For detailed information, please refer to the EJOT company standard.

You can download these in our service area "CAD & more".

Click here to register: "CAD & more"